- On 2002, UCF had modified its existing management system to comply with requirements of ISO 9002 : 94.

- On 2003, UCF had modified its management system to comply with requirements of ISO 9001 : 2000.

- On 2005, UCF had, once again, modified its management system to adopt and declare its environmental commitment, thus complying with requirements of ISO 14001 : 2004.

- On 2009, UCF management system was modified as per ISO 9001 : 2008 requirements.

- On 2010, UCF management has adopted new specific policies and values that enable UCF to satisfy international market requirements.

UCF is awarded ISO 9001 : 2015 and ISO 14001 : 2015 applicable to :

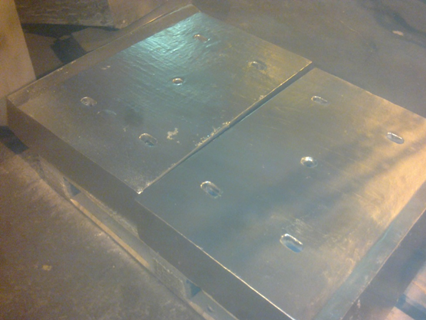

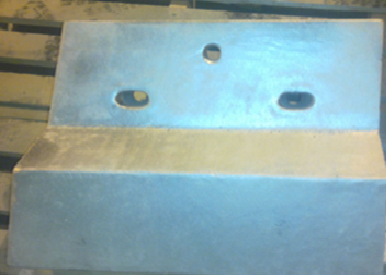

- Plain carbon and alloy steel castings

- Wear, corrosion and heat resistant steel casting

- Chromium iron castings

- Fabricated wrought steel products

- Foundry patterns.in all its work sites and locations.

In all it's work sites and locations

- As per UCF Quality plans of products , there are process control activities implemented by production dept. and an in –process inspection activities implemented by quality dept.

The process control and the in – process inspection plans of a definite production process shows :

- Aspects need to be measured or tested

- Frequency of testing or measuring

- Means of testing or measuring

- Responsible body of carrying out this testing

- The quality form used for recording testing results

- Specification or criterion of evaluating the testing results.

- UCF is committed to continual improvement of all its processes and its integrated management system. This commitment is the only way for realizing its customer satisfaction and expectations.

- QUALITY is one of the main features of the processes, products and services that UCF offers its customers all over the world.

- Each stage in the process, from the design, material purchasing manufacturing, inspection & testing, and dispatch to the customer is supervised and controlled according to UCF internal procedures and specifications of its Quality Management System, in compliance with the ISO 9001 standard.

- The industrial and quality management processes are continually reviewed and improved through conducting internal and external audits by customers or other monitoring bodies.

- UCF laboratories testing the finished products are spectrometer laboratory, sand testing laboratory, mechanical laboratory, and metallographic laboratory.

- UCF Consider the customer expectations as the most valuable opportunity for improvement.