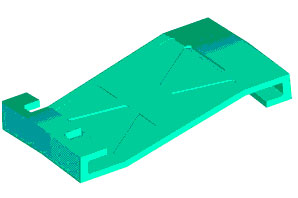

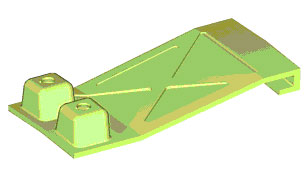

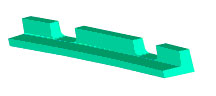

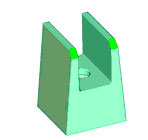

UCF produces wide varieties of fabricated products such as : - Diaphragm plates manufactured from hot rolled steel sheets - Bolts for fixation of liners. They are manufactured by hot forging. Threads are made by thread rolling machine. - Ball sorting machines for classifying balls according to their diameters. - Anchors - Nuts and washers - All machining operations as per the customer requirements. - Diaphragm structure. - pins, rods, wheels, rollers … etc.

- Call Us: (0554) 410504

-

info@asec-united.com

UCF standard alloys for heat resistant applications include more than 20 alloys that withstand temperatures up to 1200 °C. These alloys have various Cr contents up to 30 % & various Ni contents up to 50 % in addition to other elements that render higher heat resistance for special applications . Examples of UCF heat resistant castings are : - Cooler plates - Inner pipe segments for preheater cyclones - Inlet and outlet segments for Kilns, e. g. nose rings - Nozzles, big blaster elbows, flaps - Grate & side plates for cooler - Brick clamps

Grinding media ( all sizes of balls from 15 : 125 mm ). They are cast from high Cr iron alloys as per the customer requirements or according to our suggestions to satisfy predetermined conditions at the customer mills.

The supplied grinding media are satisfying working conditions in first and second compartments of cement, raw, and also coal mills.UCF is supplying grinding balls of various Cr contents as 12 %, 17 %,19 %, 21 %, 27 %, thus adapting different mills operating conditions.

Balls of 17 : 40 mm diam. are cast from various high Cr alloys containing 12 up to 33 % Cr satisfying a hardness of 60 – 67 HRC.

Balls of 50 : 110 mm diam. are cast from various alloys containing 17 up to 30 % Cr satisfying a hardness of 58 – 63 HRC.

Balls of 125 mm diam. are cast from ARB – 03 and used for mining applications satisfying 2.0 – 3.0 % Cr and hardness of 51 – 54 HRC.

UCF is also producing cast cylpebs and ballpebs in the following sizes :

Cylpebs sizes :

1- 16 x 16

2- 19 x 19

3- 22 x 22

4- 25 x 25

5- 25 x 30

6- 35 x 35

7- 35 x 40

Ballpebs sizes :

1- 19 x 24

2- 13 x 16

3- 16 x 20

4- 22 x 28

Normally UCF technical team studies the mill operational conditions and supply guaranteed grinding media to its customers. The guarantees include wear rate guarantee, breakage guarantee, and deformation guarantee.

More Articles...

Subcategories

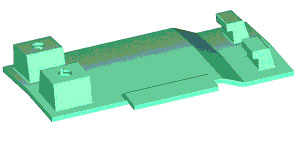

inner pipe segments

- Default

- Title

- Date

- Random

-

0

0 -

0

0 -

0

0 -

0

0 -

0

0